$25.69

Save 22%

>>>>

Safety Glasses, Goggles & Accessories

Shop Safety Glasses, Goggles & Accessories

(168 Products)

Sort by:

Best match

Ergodyne Skullerz VALI Anti-Fog Safety Glasses, Frameless, Smoke Lens (59233)

Item #: 901-24478929

Frameless safety glasses keep your eyes safe during outdoor activities and in bright-light environments

Rimless design with matte black side arms maximizes the field of vision

Smoke lens tint

$10.79

Per each

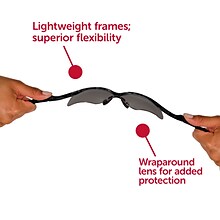

KleenGuard Nemesis Safety Glasses, Wraparound, Blue Lens (14481)

Item #: 901-318488

Sporty, flexible lightweight design soft-touch temples for added comfort single-lens wraparound protection

Frame design: Wraparound

Lens tint/frame color: Blue/black

$11.19

Per each

Bausch & Lomb Sight Savers Window & Glass Cleaner, 100/Box (8574GM)

Item #: 901-BAL8574GM

Unscented wipes are perfect for glasses, face shields, glass lenses, plastic lenses, etc.

Sold as 100 per box

Pre-moistened for immediate use

$16.39

Per box

Bouton Optical Lens Cleaning Towelettes, 100/Box (252-LCT100)

Item #: 901-560727ORS

Dispenser filled with pre-moistened towelettes that can be used for cleaning plastic, glass, and polycarbonate lenses on safety goggles, face shields, and eyewear

Chemicals: isopropyl alcohol (10%), water, antistatic, and detergent

Contains 100 individually packaged towelettes per dispenser

$23.49

Per box

MCR Safety Checklite Polycarbonate Safety Glasses, Clear Lens, 12/Pack (CL110)

Item #: 901-197774ORS

Safety glasses give you a comfortable feel and are good for everyday use or a new visitor spec

Glasses feature clear polycarbonate lenses

Meets or exceeds ANSI Z87+ and CSA Z94.3 standards

$32.69

Per pack

Jackson Safety Nemesis Polycarbonate Safety Glasses, Smoke Mirror Lens (25688)

Item #: 901-422542

Safety glasses are comfortable and functional for construction, manufacturing, and other industries

Glasses feature a black frame with polycarbonate lenses in the smoke mirror coating

Meets or exceeds ANSI Z87.1+ standard

$12.89

Per each

Checklite® Safety Glasses, Scratch Resistant, Gray Frame & Lens

Item #: 901-2579080

Duramass® scratch resistant coated safety glasses

Good for everyday use or a new visitor spec

Smaller frame sized to fit smaller faces

$2.29

Per pair

Fendall Eyesaline Solution Refill (32-000455-0000)

Item #: 901-846437ORS

Eyewash bottle refill

Bottle capacity is 32 oz.

Sealed, sterile bottle contains a buffered saline solution - superior to tap water for eye care

$19.99

Per each

MCR Safety BearKat Polycarbonate Safety Glasses, Clear Lens (BK110)

Item #: 901-197770ORS

Glasses feature clear polycarbonate lenses

Meets ANSI Z87+ and CSA Z94.3

Comfort is enhanced by the flexible temples, and the non-slip temple sleeves are notched for a clip-on breakaway cord

$4.09

Per pair

Bouton Glasses, Anser Black Frame, Clear Lens and Anti-Scratch/Anti-Fog Coating, Each (250-AN-10111)

Item #: 901-2763759

Wraparound temples with rubberized tips gently grip the wearer's head.

Lightweight, semi-rimless design provides all day user comfort

Sleek, sporty style with wraparound lens protection

$8.69

Per each

Fendall Eyesaline Double Station, 32 oz. (32-000462-0000)

Item #: 901-423309

Double eyewash wall station for immediate flushing

Bottles capacity is 32 oz.

Sealed, sterile bottles contain a buffered saline solution - superior to tap water for eye care

$110.49

Per each

Honeywell Eyesaline Solution Refill, 12/Carton (320004540)

Item #: 901-320004540CT

Eyewash bottle refill

Bottle capacity is 16 oz.

Sealed, sterile bottles contain a buffered saline solution - superior to tap water for eye care

$184.09

Per carton

Featured

PhysiciansCare Eye Wash, 8 oz. (24-050)

Item #: 901-71345

(1) 8 oz. bottles of sterile isotonic buffered solution

Helps to clear eyes of foreign material

Plastic squeeze bottle and nozzle create a direct fluid stream

$12.29

Per each

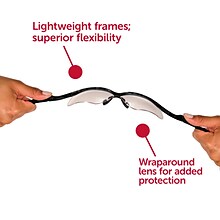

Jackson Safety Nemesis Polycarbonate Safety Glasses, Clear Lens (25679)

Item #: 901-422541

Safety glasses are comfortable and functional for construction, manufacturing, and other industries

Glasses feature a black frame with polycarbonate lenses in clear, anti-fog coating

Meets or exceeds ANSI Z87.1+ standard

$12.29

Per each

Jackson Safety Nemesis Polycarbonate Safety Glasses, Clear Lens (25676)

Item #: 901-422540

Safety glasses are comfortable and functional for construction, manufacturing, and other industries

Glasses feature a black frame with clear polycarbonate lenses

Meets or exceeds ANSI Z87.1+ standard

$10.19

Per each

MCR Safety Crews Checkmate® Glasses, Flexible Bayonet Temples, Clear Tint & Frame (CREWS)

Item #: 901-560743ORS

Color: Clear with clear frame

Lens material: Polycarbonate

99.9% UV protection

$5.99

Per each

MCR Safety BearKat Polycarbonate Safety Glasses, Clear Lens, 12/Pack (135-BK110XX)

Item #: 901-24564922

Glasses feature clear polycarbonate lenses

Meets ANSI Z87+ and CSA Z94.3

Comfort is enhanced by the flexible temples, and the non-slip temple sleeves are notched for a clip-on breakaway cord

$36.79

Per pack

Fendall Eyesaline Eyewash Solution (32-000454-0000)

Item #: 901-423307RDR

Eyewash bottle refill

Bottle capacity is 16 oz.

Sealed, sterile bottles contain a buffered saline solution - superior to tap water for eye care

$29.69

Per each

Ergodyne Skullerz VALI Safety Glasses, Frameless, Smoke Lens (59230)

Item #: 901-24478818

Frameless safety glasses keep your eyes safe during outdoor activities and in bright-light environments

Rimless design with matte black side arms maximizes the field of vision

Smoke lens tint

$9.69

Per each

Crews® Safety Goggles-Over Glasses; Chemical Safety, Clear Lens (CRW2230R)

Item #: 901-22301Q

Rugged construction

Can be worn with most half-mask respirators

Transparent protective PVC body with clear lens

$15.29

Per each

MCR Safety Checklite CL110 Safety Glasses, Clear (CL110EA)

Item #: 901-197774

Lens tint/frame color: Clear

Lens material: Polycarbonate

Filters 99% of U.V. radiation

$3.09

Per each

3M™ 334 Polycarbonate Safety Splash OTG Goggles, Clear Lens (40660)

Item #: 901-854129

Economical goggle

Indirect-venting system designed to circulate air and help minimize fogging while keeping liquids out

Over-the-glass coverage

$9.99

Per each

MCR Safety® Law® OTG Safety Glasses, Clear Anti-Fog Lens, Silver Temple, 12/Pack

Item #: 901-197778ORS

Safety Glasses

Eye Protection

Polycarbonate

$99.19

Per pack

Bouton® Zenon Z12 Glasses, Black Temple, Clear Lens, Foam Padding and Anti-Scratch / Anti-Fog Coating (250-01-F020)

Item #: 901-2764051

Safety Glass

Protects your eyes from injury

Anti-scratch and anti-fog coating on lenses

$13.29

Per pair