Shop Binding Machines

(10 Products)

Filter by:

Sort by:

Best match

Fellowes Pulsar+ 5006801 Comb Binding Machine & Plastic Comb Binding Spine - Special Offer!

Item #: 901-CD15006801

Medium-duty comb binding machine ideal for small office use

Binds up to 300 sheets

Dimensions: 5.13"H x 18.3"W x 15.38"D

Fellowes Star+ Comb Binding Machine, 150 Sheet Capacity, White/Black (5006501)

Item #: 901-5006501

Light-duty comb binding machine for small office use

Binds up to 150 sheets

Dimensions: 3.13"H x 17.69"W x 9.81"D

Fellowes Pulsar+ Comb Binding Machine, 300 Sheet Capacity, White/Black (5006801)

Item #: 901-5006801

Medium-duty comb binding machine ideal for small office use

Binds up to 300 sheets, maximum length of the document is letter size (8.5 x11 inches)

Dimensions: 5.13"H x 18.3"W x 15.38"D

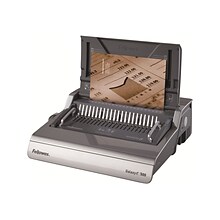

Fellowes Galaxy-E Comb Binding Machine, 500 Sheet Capacity, Metallic Silver/Black (5218301)

Item #: 901-5218301

Heavy-duty electric comb binding machine ideal for frequent large office use

Binds up to 500 sheets

Dimensions: 6.5"H x 17.75"W x 19.63"D

Fellowes Pulsar-E Comb Binding Machine, 300 Sheet Capacity, White/Black (5216701)

Item #: 901-5216701

Professional-Grade Binding: Create polished booklets, manuals, and presentations with ease using this medium-duty comb binding machine.

High Binding Capacity: Binds up to 300 sheets, with a maximum comb size of 1.5" (38mm) making it ideal for employee handbooks, training guides, and business reports.

Efficient Punching Power: Punches up to 20 sheets at once with vertical document loading for precise alignment and clean results.

Fellowes Quasar-E Comb Binding Machine, 500 Sheet Capacity, Metallic Silver/Black (5216901)

Item #: 901-5216901

Medium-duty electric comb binding machine ideal for large office use

Binds up to 500 sheets

Dimensions: 5.13"H x 16.88"W x 15.38"D

Fellowes Helios 30 Thermal Binding Machine, 300 Sheet Capacity, Charcoal and Silver (5219301)

Item #: 901-5219301

Charcoal metallic/silver

Size: 3 15/16"H x 20 7/8"W x 9 7/16"D

Binding sheet capacity: 300

Formax FD 1202 Automatic Pressure Sealer, 160 Sheets (FD1202)

Item #: 901-1882532

Made in the USA

Compact desktop design with user-friendly features provides easy installation and operation

Folds Z, C, Uneven Z, Uneven C, Half and custom folds

Fellowes Quasar+ Comb Binding Machine, 500 Sheet Capacity, Metallic Silver/Black (5227201)

Item #: 901-70460Q

Medium-duty comb binding machine ideal for large office use

Binds up to 500 sheets

Dimensions: 5.13"H x 18.13"W x 15.38"D

Fellowes Lyra Patented 3-in1 Comb Binding Machine, 30 Sheet Capacity, White/Gray (5603001)

Item #: 901-24441790

Combines stapling 3-hole punching and comb binding in one machine

EasyPress double action stapler offers effortless stapling for up to 30 pages

Comb binds documents up to 300 pages, comb punches 20 sheets, 3-hole punches 30 sheets