Shop Lock Out Tags

(21 Products)Lockout tag types

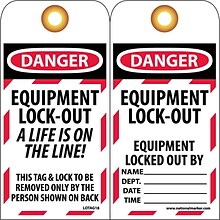

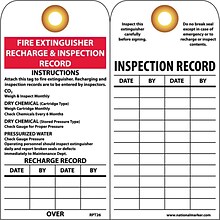

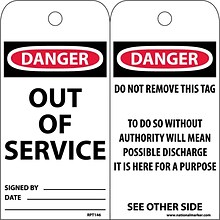

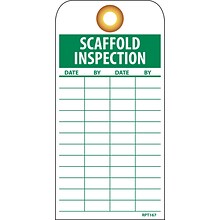

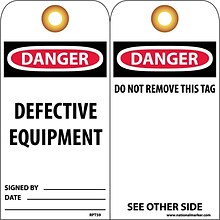

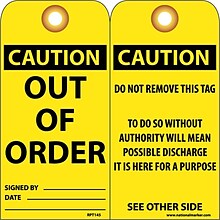

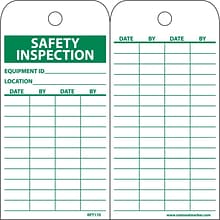

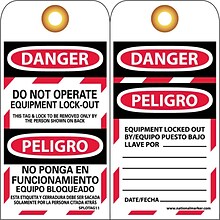

Lockout tagout tags are designed with holes at the top to fit inside locks which are used to prevent the use of a defective machine. The tags are there to inform users of the dangers. There are a few types that tell employees just how dangerous the situation is. Danger or warning safety signs have big bold letters that tell users of serious risk and warn them not to use a defective machine or of chemical leakage hazard. Caution or notice tags provide a slight warning about potential issues such as machinery being repaired, or barricading an area of the factory. Informational office signs have space to write useful notes, such as last inspections, emergency shower usage, or lists of hazardous materials.

Lockout tagout tag materials

The types of material used to make these safety supplies varies and affects the lasting ability of the product. Common materials used to make LOTO tags include:

- Plastic, which is available in bulk for labeling lots of machinery

- Vinyl, which is flexible but won't tear or rip

- Aluminum, which is lightweight and sturdy

- Durable metal, for tags that last for years

Lockout tag safety regulations

Most lockout tagout tags fulfill OSHA standards for safety in the workplace. This means they are durable and won’t become unreadable when in contact with chemicals or water. It also means they are colored and printed in such a way that users can see the warning easily. OSHA also requires labels to have sections to write dates, information, and authorized employees allowed to use the tag out system. It is also recommended to have state and federal labor law posters on walls in the factory that explain the lockout tagout procedure for all employees.